What is an electrical contractor?

Contactors are electromechanical control device that uses a contactor to create or break an electrical connection that connects the load to the power supply. The device used in applications that require a higher current is referred to as a contractor, and the one used for applications with a lower current is called a relay. In this article, you will also learn about different types of contactors.

Contactors can have several contacts depending on the app and load. The majority of the contacts are usually in open (NO) contacts. The load is cut off when the contactor’s coil is removed from energized. The contactor may be designed for normally closed and normally closed applications. The most commonly used application for contactors is the starter used to turn on and off equipment like a motor, transformer, or other equipment.

Contactors are powered by much less powerful circuits than the circuit it controls. Contactors are usually used in conjunction with a 150 HP motor.

Magnetic contactors are devices or switches that operate using magnetic energy and shut or open the electrical circuit as needed. Further details are available here.

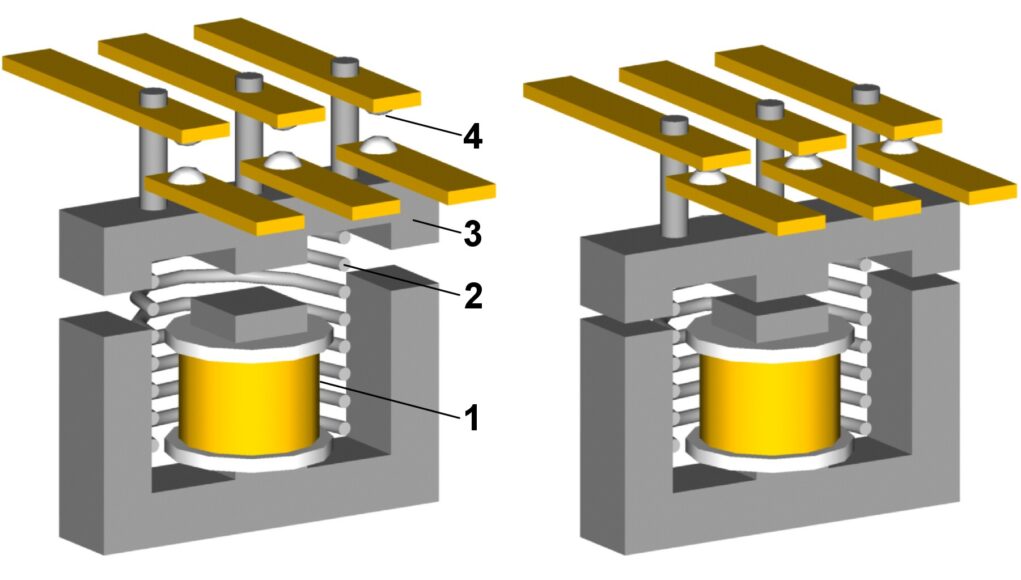

The construction of a contactor

Contactors come in three primary components:

- Electromagnet or Coil

- Frame, or enclosure

- Contacts

Electromagnet

A coil of this kind is wound around an electromagnetic core and acts in the form of an electromagnetic. In general, it comprises two components, and one is a fixed component while the other is a moving part. Thus, there’s an arrangement for spring return. The rod is linked to the moving component. The rode can also be referred to in the field of armatures.

A small amount of current flows through the spring to activate the magnetic core, either from the source or the external control circuits. For AC applications, the electromagnetic core is composed of soft iron that has been laminated to limit the current of the eddy. The core is composed of steel solid.

Frame or Encloser

The enclosure helps safeguard the internal components inside the contactor. It is composed of nylon 6, plastic ceramic, ceramic, or Bakelite. It is used to house the electromagnet as well as contacts. The enclosure helps isolate the contacts and offers protection from dust and weather elements, oil, and other explosion dangers.

Contacts

This is the only part where the full load current flows. This makes it the most crucial part that makes up the contactor.

The material used for contacts is a stable material with high arcane resistance and high resistance to welding. The materials used for the contacts must withstand the effects of physical stress and erosion and the arc. Its resistance is the lowest possible since the entire load current can pass over the connections. In the case of low current, the contacts consist of silver cadmium oxide and nickel. For high-current use and current DC, it’s composed of silver Tin oxide.

The electromagnet’s armature is connected to the contact that moves. Therefore, the contact that is moving changes position in response to the actions of an electromagnet. The electromagnet connects or disconnects from the static contact.

The workings of contactor

The electromagnetic field is created when an electromagnetic coil is activated. As we’ve seen in the building, the contactor’s moving point the contactor is linked to the armor (metallic rod) of an electromagnet.

When an electromagnetic field has created an armature, it is subjected to the force and pulls toward that fixed point. The contacts stay in this position as long as the coil has not been de-energized.

After the coil has been removed from the coil, the force of electromagnetic is at zero, and the armature is pulled back by spring force. Then it returns to the normal state (OFF state). Contactors are specifically designed to operate quickly on and off.

The contactor’s input coil could comprise AC or DC. The universal coil can be employed for an electric coil in certain situations. Universal coils work using AC and DC, respectively. A tiny percentage of power loss happens in the contacts. An Economizer circuit is employed to minimize this loss.

When making and breaking contacts, arcs are created in between contacts. As a result of arcs, dangerous gases are generated, like mono-oxide. Therefore, various ways are used to limit and eliminate the arcs.

The contacts are selected based on voltage and load current and the controlled voltage range, and the application dependent on the utilization category. If you’d like to determine whether the contacts’ connections are closed or open, you want to check this using an ohmmeter. Connect the ohmmeter to the output and input contacts.

Types of contactors

Knife Blade Switch

It is made up of a metallic strip that has a lever. It is an automatic contactor. It isn’t easy to quickly turn on and off by hand.

The entire load current will flow through the contacts and, consequently, for large motors, the load current is exceptionally high. There is a possibility of arc creation between the contacts in this case. It is hard to stop the arches. The other issue is the loss of power. Because the current is extremely high, much power will be lost due to the contacts. The third issue is security. This type of contactor requires improvements. The life span of this contactor is relatively short because there is a risk of the contacts rusting due to moisture. Because of the difficulties and dangers of operation, this type of contactor is seldom used.

The manual contactor (double break contactor)

There are many disadvantages of contractors that use knife blades. Therefore, to beat these limitations, the manual contactor was created. This kind of contactor is secure to operate even with a smaller size.

It lets you utilize more current within a smaller space. Double break contacts split the connection and make two contacts. As the name suggests, it isn’t controlled by wireless or remote, requiring manual control.

Read More: A Comprehensive Guide About What Is Rheostat And What Is Rheostat Function With Its Top Applications

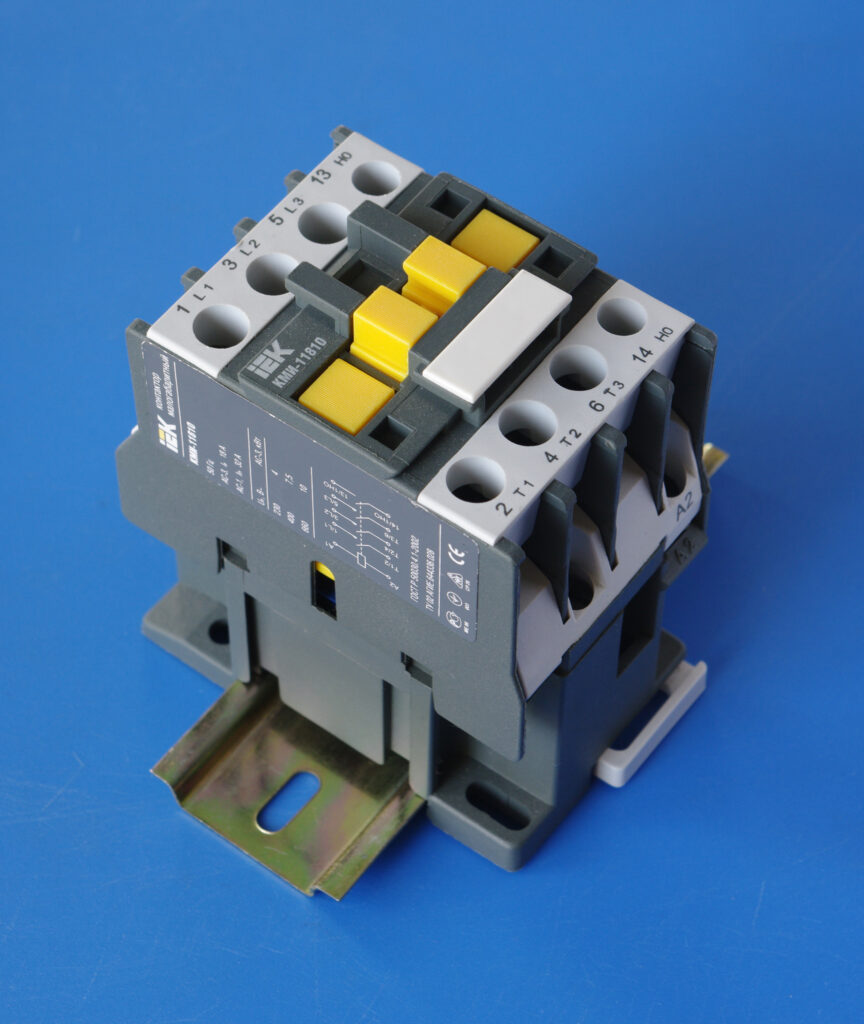

Magnetic contactor

Its design for this kind of contractor is among the most modern among other kinds of contractors. It is an electromagnetic contactor that operates entirely automatically. It needs a tiny amount of a control circuit to switch off and on the load. This means that its operation with this device is safer than with manual contactors. This is the most frequently used contactor for industrial use. It works electromechanically, and as such, it requires a small amount of power to establish a connection between the power supply and the load.

What’s the distinction between relay and contactor?

- The contactor is utilized to switch high voltages, and the relay is employed in low voltage switching applications. If your load’s current exceeds greater than 15A, contractors are employed. If the current of the load is less than 15A, the relay will be utilized.

- The contactor’s dimension is enormous compared to the relay’s size.

- Maintenance of the contactors is straightforward, however, under most circumstances, the relay will not be able to be repaired.

- In the majority of cases, the contactors are connected as ordinarily open contacts, and they are then connected to the relays are connected in regular closed contacts.

- The time to switch the contactor is sluggish in comparison with the relay.

Uses of contractor

Electrical contactors are used in various situations where power needs to be switched repeatedly to a circuit. These switches are designed and built to perform this task over thousands of cycles, like relay switches.

In contrast to relays, contactors are mainly used in high-power applications. Low voltages and currents can switch on and off a circuit with far higher voltages and currents due to their ability to power cycle.

A contactor is typically used when power loads need to be turned on and off frequently or rapidly. However, they can also be set to turn on a circuit when activated (ordinarily open or NO contacts) or shut it off when activated (customarily closed or NC contacts).

Electric motor starters – those that use auxiliary contacts and connectors in electric vehicles – and high-powered lighting control systems are two classic applications for contractors.

FAQs

Apart from this if you are interested to know more about Hiring Contractors The Right Way then visit our BUSINESS category.