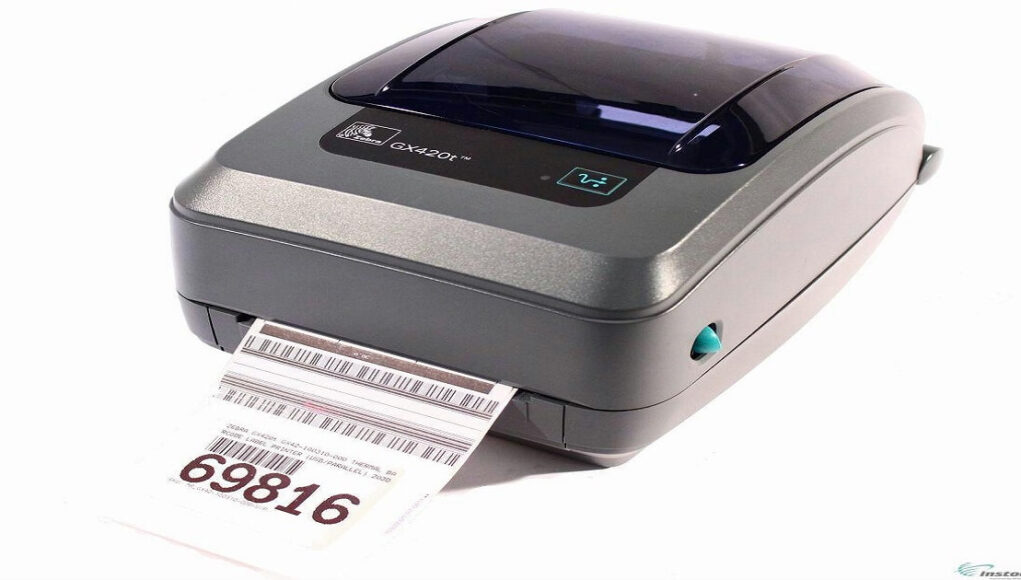

Thermal Transfer Label Printer are excellent at printing barcode labels and cards, but do you frequently send a repair technician to service your printer? Maintain print quality and extend the life of worn-out components such as print heads and rollers. Here are some simple tips for increasing the volume. Thermal Transfer Label Printer have a lot of uses. They also come in a lot of sizes and shapes. From small desktop units offered by carriers like UPS and FedEx to larger units that can be used as all-in-one or stand-alone printers in packaging, warehousing, and production environments.

There are two ways to use the thermal printer. If a thermal printer uses ink ribbon, then that is called a Thermal Transfer Label Printer. In other words, the printer transfers heat from the print head to the tape, which melts the ink at a specific temperature and “transfers” the ink to the media material, such as labels and tags. Another method is “direct thermal” printing. This method does not use tape. The media (labels or tags) must be direct thermal media to use direct thermal printing. This media type contains a “heat-sensitive” chemical coating that changes color at specific temperatures. The most common color is black. The printer transfers heat from the print head “directly” to the media. It is the media that changes color in response to the temperature of the printer.

Tip 1: Keep the print head clean.

Read the operator’s manual and follow the manufacturer’s recommendations for cleaning the print head. Generally, it would be best to clean the head with isopropyl alcohol at a concentration of 70% or higher. The print head must be cleaned for Thermal Transfer Label Printer when changing the tape. It would be best if you cleaned the print head of the direct thermal printer when changing media.

Tip 2: Do not use sharp objects to remove sticker jams

Thermal Transfer Label Printer have a printing drum made of a rubber compound that pushes the media out of the front of the printer. This roller also provides back pressure on the print head, thus completing the printing. If the roller is cut, this soft spot will not be printed clearly and will appear as a recurring faint spot on the label. This may not be a big problem for descriptive labels, but it is unsuitable for barcodes. Also, clean the printing roller with alcohol once a week to prevent a buildup of residue that can cause long-term problems.

Tip 3: Blow the dust at least once or twice a month

Air and media dust build up inside the printer over time. Dust buildup can cause print quality and sensor problems. Use a dry compressed air source (canister or compressor) to blow up the printer. If you are using an air can, do not spray liquid from the canister onto the printer. This freezes quickly and accumulates moisture when thawed. Using a compressor, use a moisture trap/filter to prevent water from escaping from the nozzle. Make sure dust does not return to the inside of the printer after it has been blown out. It is common for the print quality to be poor for the first few labels as dust explodes and falls on the labels as they are being printed. It is often a good idea to feed or print media a few feet in size to remove any loose dust that may remain inside the printer.

Tip 4: Check the resolution of your printer

203 “dots per inch” (DPI) is the standard resolution for thermal printers. This resolution is suitable for more prominent labels and less dense barcodes. Another average volume is 300 dpi. This resolution is ideal for large- to medium-sized brands with moderate barcode density. Some manufacturers produce print heads with a resolution of 600 dpi or higher. Suitable for small labels and high-density barcode labels. As the accuracy of the head increases, the cost of replacing the head increases. Also, the higher the resolution, the more data is processed to create the printed image. As a result, the maximum print speed is usually reduced.

All manufacturers have slight differences in user maintenance. It is highly recommended to follow the instructions in the manual for optimum results. If you can’t find a user manual or manual, these tips will help you increase the print quality of your Thermal Transfer Label Printer and the longevity of your wearable parts.